Gate 250m³ /H Compost Fertilizer Making Machine Agriculture Machine Agriculture Machinery Equipment Farm

Overview Groove Type Compost Turner Product Description Organic Fertilizer Raw Materials 1. Agricultural wastes: such as

Basic Info

| Model NO. | CFD-012 |

| After-sales Service | Remote Video Guidance |

| Warranty | 1-5years |

| Type | Compost Turner |

| Voltage | 220V |

| Certification | CE, ISO |

| Tipping Height | 600-1500mm |

| Overturning Width | 2400-4000mm |

| Output | 180-250 M3/H |

| Transport Package | Standard Wooden Package |

| Specification | 180-250 m3/h |

| Trademark | GATE |

| Origin | China |

| Production Capacity | 500-1500 M3/H |

Product Description

Groove Type Compost TurnerProduct Description

Organic Fertilizer Raw Materials

1. Agricultural wastes: such as straw, soybean meal, cotton meal, mushroom residue, biogas residue, fungus residue, lignin residue, etc.2. Livestock and poultry dung: such as chicken dung, cow, sheep and horse dung, rabbit dung;3. Industrial waste: such as distiller's grains, vinegar grains, cassava residue, sugar residue, furfural residue, etc;4. Domestic waste: such as kitchen waste;5. Urban sludge: such as river sludge, sewage sludge, etc. Classification of Chinese organic fertilizer raw materials: mushroom dregs, kelp dregs, phosphocitric acid dregs, cassava dregs, sugar aldehyde dregs, amino acid humic acid, oil dregs, shell powder, etc., and peanut shell powder.Scope Of ApplicationAccording to the principles of microbial fermentation, suitable for the process requirements of microbial fermentation, fermenting bacteria have space to play their functions. They evenly mix the thick animal manure with microbial preparations and straw powder to make suitable aerobic environment for material fermentation

Manufacturing technologyThe machine is a reinforced concrete structure, and the adjacent two machines share the wall. The width of the wall is determined according to the requirements of the tipper and can withstand the pressure of the tipper. The mechanical bottom plate must withstand the gravity of the fermentation material, the gravity of the loader, and meet the requirements of ventilationHeap turning process

The motor directly transfers the power to the cycloidal pin wheel reducer to the pile roller through the sprocket, and the stirring blades on the roller are in spiral distribution. The material inside the machine can be turned and stirred 0.7-1m, with the effect of quick turning and stirring, so that the material and the air are fully in contact, to achieve better fermentation effect. Centralized controlControl cabinet centralized control can achieve manual or automatic control function, durable scraper has a certain function of cutting and mixing, limit stroke switch plays a safe limit role

What Can I Do For You

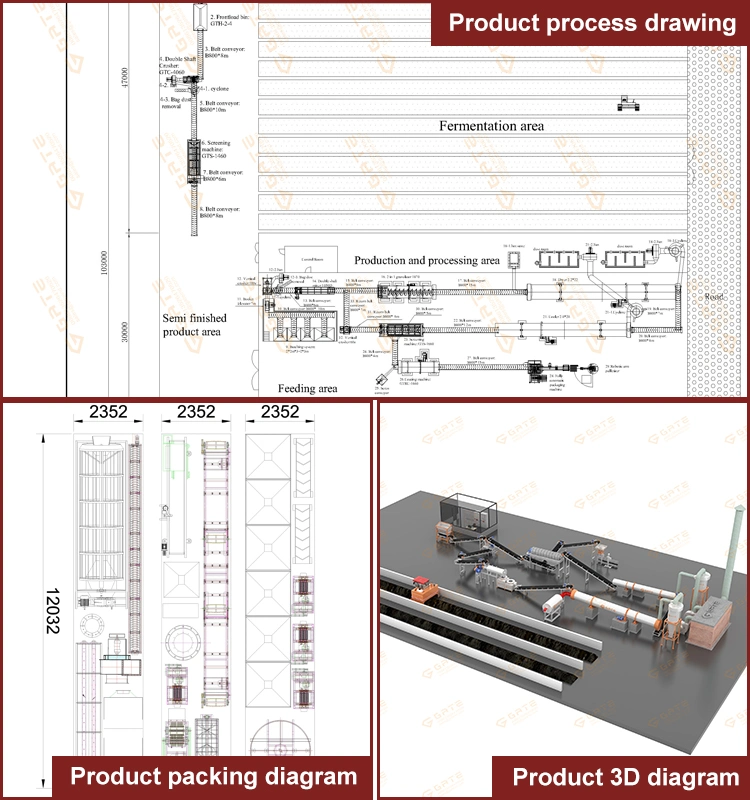

What Can I Do For You Pre-sale

Our account manager will communicate with you the product requirements related to your machine We offer free product plans, packaging drawings and 3D renderings to save your budget We will provide our own quotation and proof of our machines We have a professional R & D department, to provide you with the most professional technical support We can make granulation experiment according to your raw materials

If you need to install, we have a professional overseas installation team We will provide you with installation drawings or a video guide for making the installation We support to provide you with free accessories within one year of purchase of machine equipment We will provide a five year warranty on important parts of the equipment

Transaction Customer

Transaction Customer

| Q: Can I use this production line to produce multi granularity particles? |

| Yes, our production line is multifunctional. We can customize ring moulds of different sizes. In this way, you can easily adjust the size of your ball. |

| Q: I know little about the fertilizer production line. How to choose the most suitable machine? |

| Just tell us your raw materials, capacity (tons / hour) and the size of the final particle product, and we will choose the machine for you according to your specific situation. |

| Q: Our workers don't know how to operate the production line. What should I do? |

| Our engineers will instruct the site workers on how to install the machines and build the workshop.And field test the production line, training workers how to operate. |

| Q: Are you a trading company or a manufacturer? |

| We have a large factory in Jiaozuo, China, covering an area of 10000 square meters. Welcome to visit. |

| Q: What's the Production Period of the Fertilizer Machine? |

| For single fertilizer machine, our production time is 7 days;and for whole fertilizer production line, our production time is no more than 30 days. |

| Q: What's the Quality Guarantee and Certifications? |

| All of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 5 years after shipment date. |

Send to us