Model 30~40 Integrated Rice Mill Unit Polishing Machine Press Machine Complete Set Rice Milling

Basic Info

| Model NO. | Model 30~40 |

| Press Series | Second |

| Condition | New |

| Customized | Non-Customized |

| Capacity | 30-40t/D |

| Power Required | 60kw |

| Overall Dimensions(L×w×h) | 7700 X 1900 X 3720mm |

| Transport Package | Wooden Case |

| Trademark | BS |

| Origin | China |

| HS Code | 84371090 |

Product Description

Model 30~40 Integrated Rice Milling Unit

1. Product Description

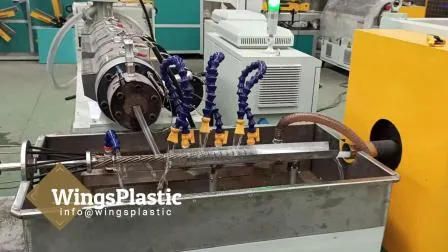

The rice milling unit procession from cleaner, destoner, husker paddy separator, rice whitener, rice grader and polisher.The Model 30~40 Integrated Rice Milling Unit is a compact and efficient machine designed for the processing of rice. It is capable of removing the husk and polishing the rice in a single pass, resulting in high-quality polished rice.The unit consists of several components, including a paddy cleaner, a husker, a separator, and a polisher. The paddy cleaner is used to remove impurities and dust from the raw paddy before it enters the milling process. The husker is responsible for removing the husk from the paddy, while the separator separates the husk from the rice grains. The polisher is used to give the rice grains a smooth and shiny finish. The Model 30~40 Integrated Rice Milling Unit is designed to be easy to operate and maintain, with minimal manual labor required. It is suitable for small and medium-sized rice mills and can process up to 1 ton of paddy per hour. The unit is also energy-efficient, with low power consumption and a high milling rate. Overall, the Model 30~40 Integrated Rice Milling Unit is an ideal choice for rice mill operators looking for a compact, efficient, and reliable machine for their milling operations.

2. Parameter

| Capacity | 30-40T/D |

| Power required | 60kw |

| Overall dimensions(L×W×H mm) | 7700×1900×3720 |

3. Necessary unit machines

• 1 TZQY/QS x 75/65 combined cleaner• 1 LTB20 husker• 1 MGCZ 100×6 paddy separator• 1 MNMF15B rice whitener• 1 MJP63×3 rice grader• 6 Elevators• 1 Electrical control cabinet

Company Profile

FAQ

Q1: What's your advantage? Why we choose you?

A: 1. Above 20 years' experience of designing, manufacturing and exporting of the grain and oil processing machinery. We have the most professional techniques and team and more advantage in price. 2. Over than 15-Years' Alibaba Gold Member. "Integrity, Quality, Commitment, Innovation" is our values.Q2: Can we mix different models and accessories together?

A: You may mix different products or models in a single container but we would need to advise you on optimum loading and final capacity of your shipment. Q3: How do I visit you and the factory?

A: You are welcomed to visit us and our factory at your convenience. We can pick you up at airport or train station and bring you to our factory . Let us know your schedule in details so we can arrange everything for you. Normally you need 3 days for an adequate visit to our factory. Q4: How can I become a dealer in my area?

A: If you are qualified, you may apply for a dealership. We choose reliable partners for a long term business cooperation. Q5: Can I get an exclusive right for your machines in some territories?

A: It depends on which country you are in. We have exclusive agents at several countries at this time. Most countries you can sell freely. Q6: After payment, how long will it take to get the machines we order?

A: Normally 30-90 days after your payment (15-45 days for manufacturing, 15 - 45 days for delivery and shipment on sea) Q7: How to order the spare parts?

A: Some machines will come with some free spare parts. We also advise you purchase some wearing parts with the machines together to stock for urgent replacement, we can send you recommended parts list. Q8: I knew nothing about these machines, what kind of machine I should choose?

A: Very easy. Let us know your idea about the capacity or budget, you will also be asked some easy questions, then we can recommend you good models according to the information.Q9: What is your warranty period?

A: Our company offer 12 months warranty since goods arrival at destination. If there is any quality problem which caused by material or workmanship fault during the warranty period, please contact us directly and we'll supply free spare parts for replacement.Q10: What is the warranty range?

A: The quality problem which caused by material or workmanship fault will be covered by warranty. The wearing parts and electric device are not included in warranty range. Any troubles and damages that caused by misplacement, misuse, improper operation, poor maintenance and non-compliance with seller's instructions will however be excluded from the guarantee.Q11: Does your price include freight?

A: Our usual price is based on FOB China. If you request CIF price including freight cost, please let us know the discharging port, we will quote freight cost according to the machine model and shipping sizeQ12: If your prices include the installation?

A: The prices for machines and installation are quoted separately. The price of machines does not include the installation cost.Q13: If you supply installation service?

A: Yes. We can send engineers to guide your local workers to install and debug the machines. The engineers will guide you install the machines, test and commissioning, as well as train your technicians on how to operate, maintain and repair the machines.Q14: What is the installation cost?

A: Here are the charges of installation services might be incurred: 1. Visa fee for engineers. 2. Traveling cost of round-trip tickets for our engineers from/to your country. 3. Lodging: the local accommodation and also ensure engineers' safety in your country. 4. Subsidy for engineers. 5. Cost for local workers and Chinese interpreter.Q15: How can I run my machines after installation? Who will operate the machines?

A: You can employ some local people or technician to work with our engineers together during installation. After installation, some of them could be trained as operator or technician to work for you.Q16: How can I do if I met problems during running the machines?

A: We will send English manuals with the machines, we will also train your own technicians. If there is still doubts during operation, you can contact us directly with your questions.Q17: What are the prices of your machines?

A: The prices are different for different models with different configurations. If you want to know more details, please send us messages right now.