Waste Plastic Pyrolysis Plant Automatic Recycling Equipment to Fuel

Package size per unit product 11800.00cm * 2200.00cm * 2450.00cm Gross weight per unit product 22000.000kg Title: Waste

Basic Info

| Model NO. | RP 1-15T |

| After-sales Service | Engineers Overseas for Technology Support |

| Warranty | 1 Year |

| Service Life | 5 - 7 Years |

| Certification | CCC, CE, ISO |

| Voltage | 380V |

| Structure | Horizontal |

| Raw Materials | Waste Tires, Rubbers, Plastics, Oil Sand |

| Application | Producing Diesel, Gasoline, Fuel Oil |

| Function | Waste Plastics Pyrolysis Process for Recycling |

| Product Type | Environmental Protection |

| Heating Fuel | Wood, Coal, Oil, Gases or Electricity |

| Working Type | Batch or Continuous |

| Tail Gases Recovery | Included |

| Online Technology Support | Whole Life |

| on-Site Technology Support | Engineers Overseas Available |

| Equipment Materials | Stainless Steel/Alloy Steel/Q235 Steel |

| Max Operation Temp. | 450 Degree Celsius or Customization |

| Min. Workshop Area | 150 Square Meters |

| Reactor Type | Horizontal Rotation |

| Sealing Type | Graphite Packing |

| Wearing Parts | Graphite Packing, Metal Gaskets and Lubricant Oil |

| Transport Package | Standard Shipping Package |

| Specification | 500 kg to 15 ton per batch |

| Trademark | BARUIE |

| Origin | Henan China |

| HS Code | 8419899090 |

| Production Capacity | 500 Kg to 15 Ton Per Batch |

Packaging & Delivery

Package size per unit product 11800.00cm * 2200.00cm * 2450.00cm Gross weight per unit product 22000.000kgProduct Description

Title: Waste plastic pyrolysis plant automatic recycling equipment to fuel

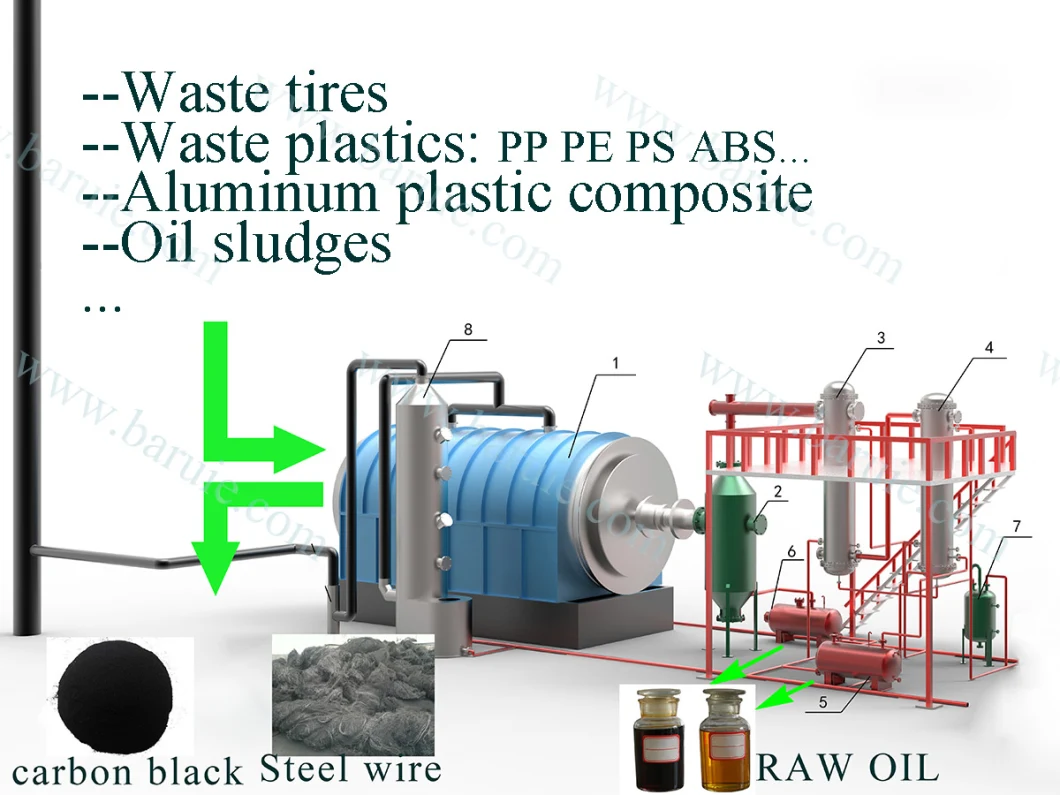

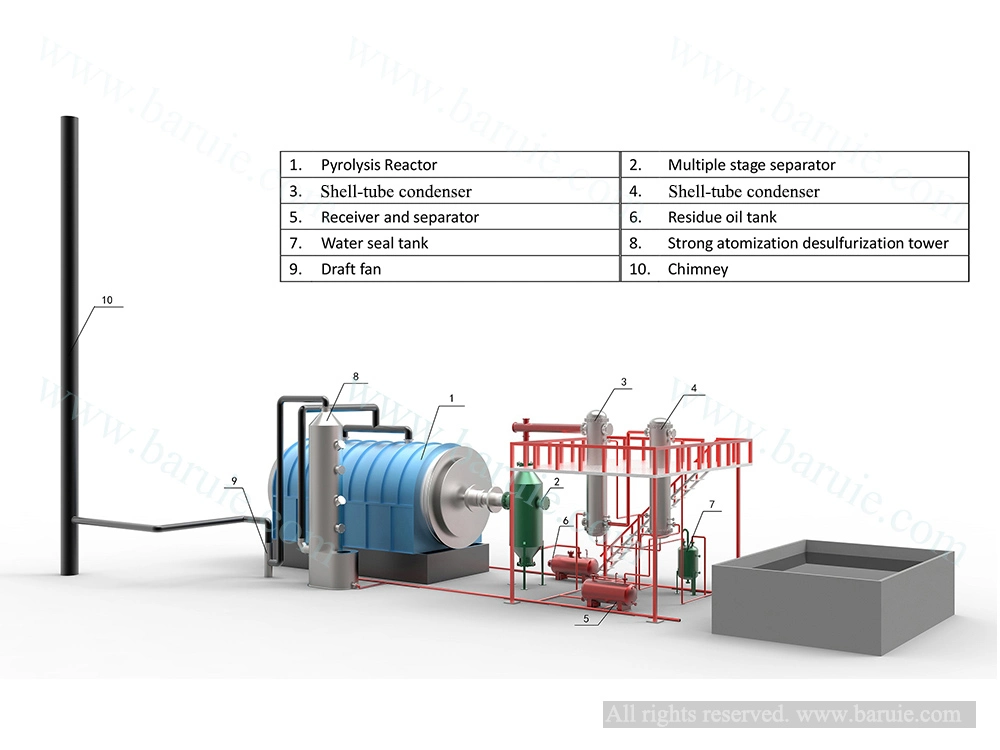

THE PYROLYSIS PLANT/MACHINE/EQUIPMENT DESIGNED BY HENAN BARUI, IS WITH REASONABLE EQUIPMENT STRUCTURE AND PROCESS OPERATION METHOD, TO RECYCLE WASTE TIRES, PLASTICS, ALUMINUM PLASTIC COMPOSITES, OIL SLUDGES AND OTHER PETROLEUM INDUSTRY PRODUCTS. THE END PRODUCTS AFTER RECYCLING ARE MAINLY FUEL OIL, CARBON BLACK AND OTHER BY-PROEDUCTS. THE DETAILS OF PYROLYSIS PLANTS ARE AS FOLLOWS:

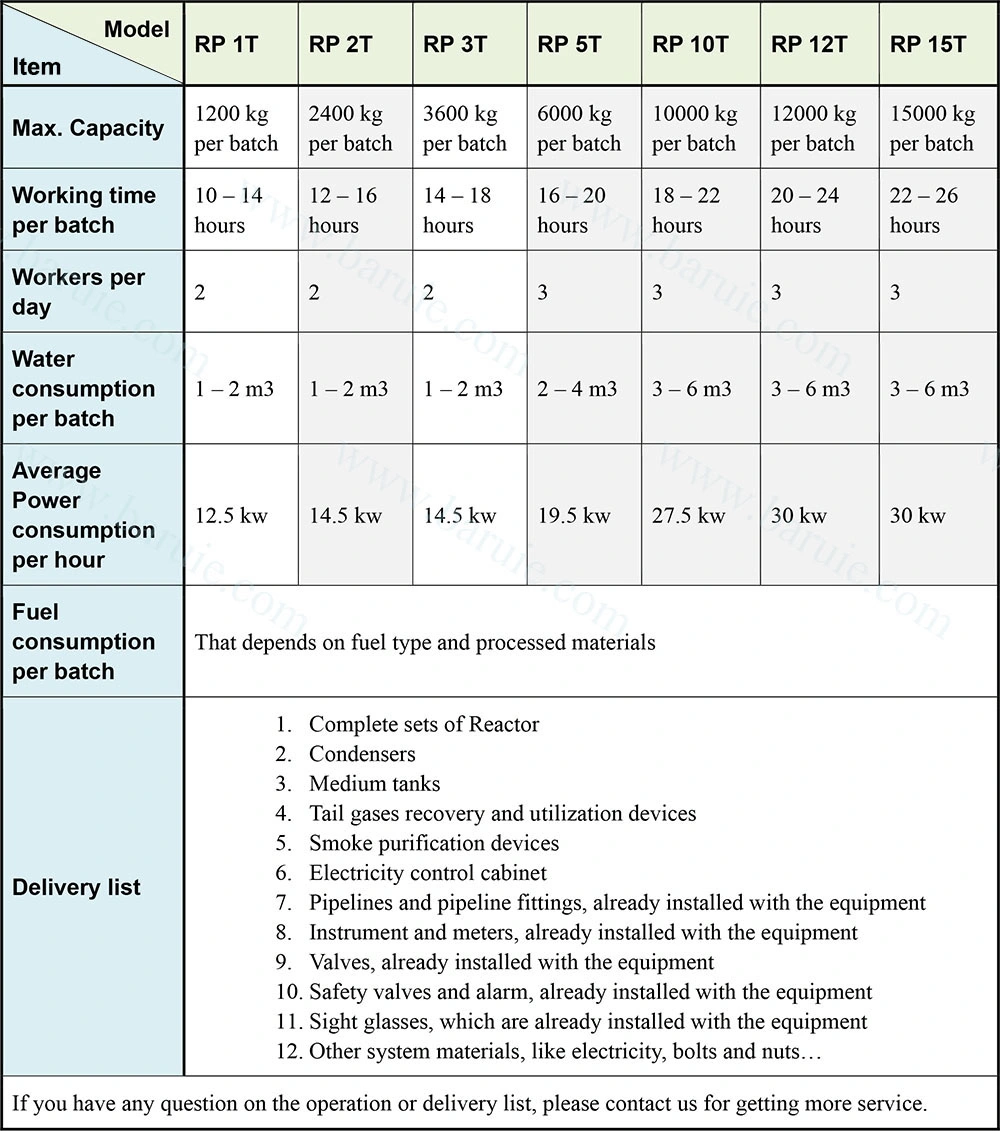

Section 1. Models of Pyrolysis Machines |

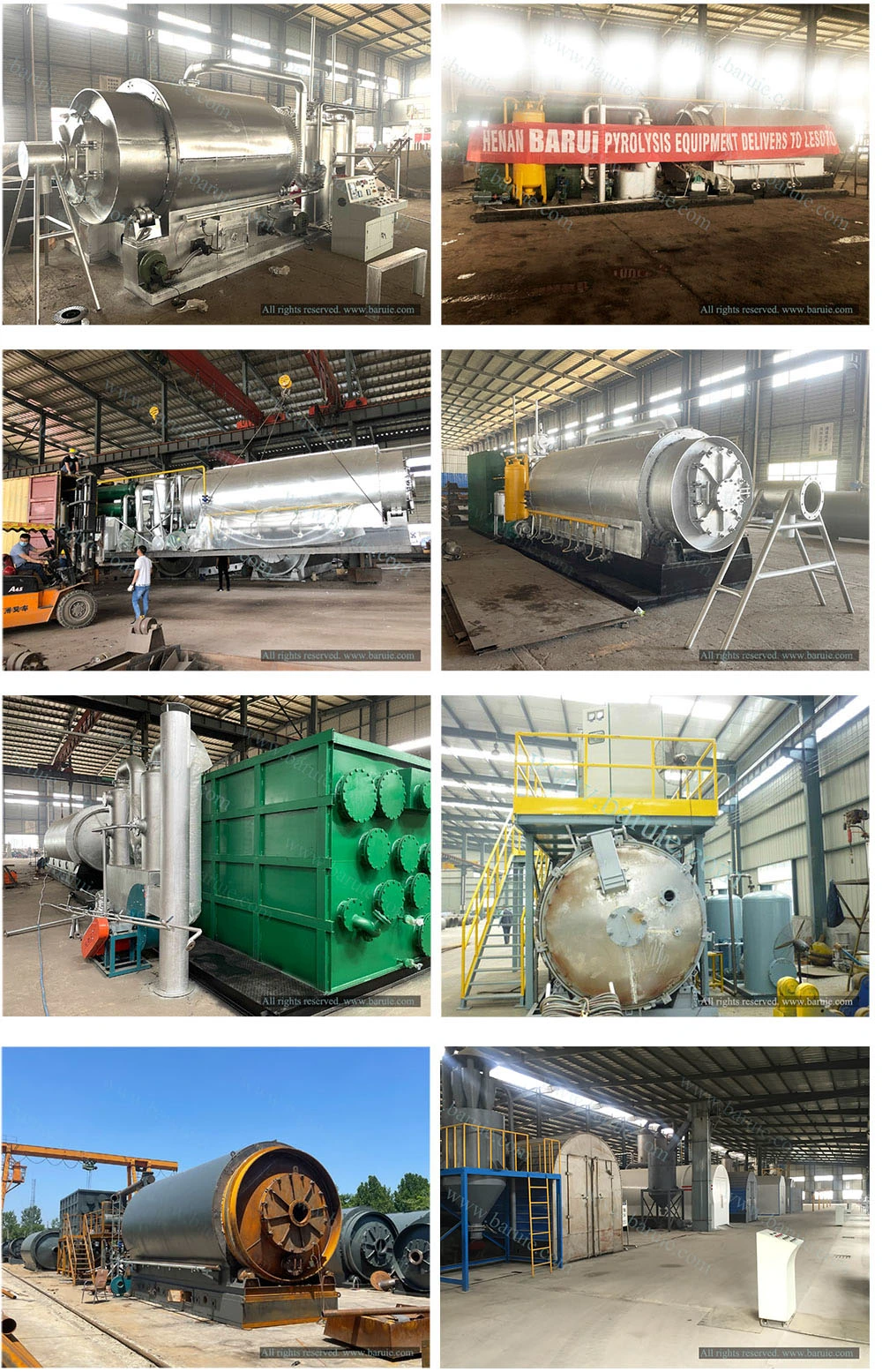

Section 2. Pictures of Pyrolysis Machines |

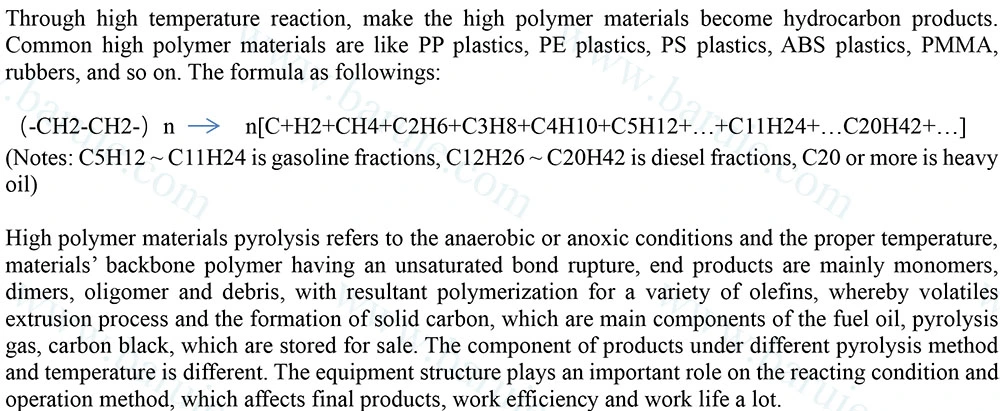

Section 3. Working Theory of Pyrolysis Process |

Section 4. Categories of Pyrolysis Machines |

So far, there is no unified standard on the classification of pyrolysis machines. According to the market convention, there are 3 commonly used classification methods: one is classified according to the raw materials of feeding pyrolysis machines, one is classified according to the installation type of pyrolysis machines, the other one is classified according to the method of raw materials feeding and slags discharging. Besides, to each classification, the pyrolysis machines are still different because the small modification is necessary for the construction environment, weather characteristics, policy and regulations, customers' special requirement, and so on. The following introduces more about the different categories of pyrolysis machines.

4.1 Classification by Raw Materials

According to different processed raw materials, pyrolysis machines are divided into tires pyrolysis machine, rubbers pyrolysis machines, plastics pyrolysis machines, aluminum plastics pyrolysis machines, oily sludge pyrolysis machines, oily sand pyrolysis machine, residue oil pyrolysis machines, and so on.

4.2 Classification by Installation Type

According to different installation type, pyrolysis machines are divided into skid-mounted type pyrolysis machines and on-site installation type pyrolysis machines. Since skid-mounted pyrolysis machines are installed and debugged in our workshop by our professional technicians and reviewed by our inspection engineer, so these machines have more advantages, like stable performance, short installation time, easy operation skill, and so on. Therefore, more and more clients prefer our skid-mounted pyrolysis machines. Besides, the advantage of on-site installation type pyrolysis machine is the lower prices. If the clients buy several reactors at once time, we can send the professional engineers to the client's factory for guiding the installation of several reactors at the same time. That can save a lot on the equipment cost.

Section 5. Introduction of Common Auxiliary Equipment |

Section 6. Equipment Manufacture Workshop Display |

Henan Barui environmental protection equipment is a comprehensive group company, which integrates technology research and design, equipment design and manufacture, equipment sales and after-sales services. The total factory land covers an area of 23 hectares, with production department, marketing department, technology department, administration department, finance department and two branches. We are committed to solid waste recycling projects, recycled oil energy projects and new energy projects. At present, the group serves many large domestic energy enterprises. International EPC project contracting is a new development strategy of the company.Following is our workshop display for equipment manufacture.

Send to us