Electrical Protection HDPE PVC Plastic Corrugated Pipe Hose Tube Extruder Machine Production Line Manufacturing Plant Equipment

16mm~40mm PP PE PVC single wall corrugated pipe production line for electrical cable/washing machine's drainage pipe wit

Basic Info

| Customized | Customized |

| Condition | New |

| After-sales Service | Provide Detail Installation and Operation Manual |

| Motor Brand | Siemens |

| Inverter Brand | ABB, or Delta, or Ls |

| Contactor | Schneider/Siemens Brand |

| Temperature Controller | Omron/Rkc/FUJI |

| Transport Package | Film, Wooden Case |

| Specification | 16/20/25/32/40 |

| Trademark | BEIERMAN |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 50-60kg/H |

Product Description

16mm~40mm PP PE PVC single wall corrugated pipe production line for electrical cable/washing machine's drainage pipe with connector

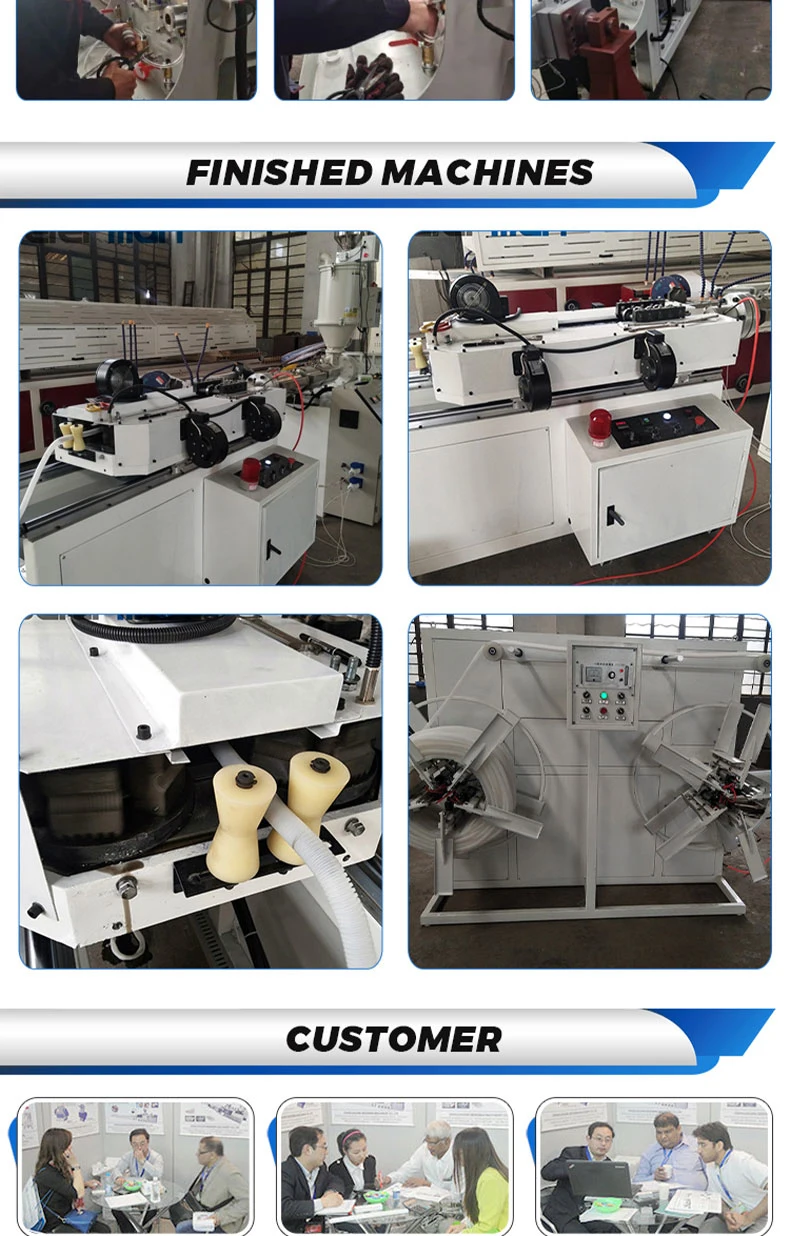

--Single screw extruder especially used for polyolefine material possess effective plasticizing effect and high extrusion speed.-- The special detached type compounding screw an die head with spiral structure & reasonable channel are applicable to produce pipes with smooth inside and outside face.--Unique calibration and cooling mode is capable of producing pipe with diameter from φ20 to φ200mm, production speed is up to 5~15m/min.--All kind of polyolefine material, multi-layers spiral strengthening pipe can be co-extruded, recycled materials can be used in production;--Optimum spiral copper sizing sleeve, its entrance carrying pre -cooling and powerful vacuum device to suit for high speed extruding pipe.Stainless steel cooling water trough is three-dimensional regulation, longitudinal moved by motor.--High efficient cooling comes from peculiar spraying nozzle and high efficiency water pump.each different pipe production line will include:

vacuum loader+hopper dryer+single screw extruder+mould+corrugated forming table and module+winder

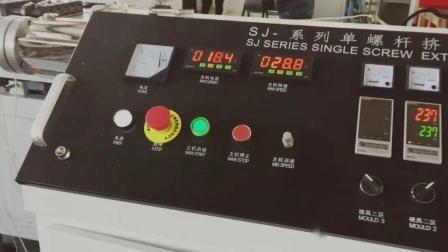

SJ65/30 single screw extruder, use PE/PP pellets as raw mateiral,settled for PE/PP single wall corrugated washing machine's drainage water pipe production line.

driving motor, 18.5KW,

Send to us